|

Automatic burner control units IFS 110IM, 111IM

ApplicationThe automatic burner control units IFS 110IM/111IM are suitable for the ignition and control of gas burners in gas firing installations of all types. These controls are designed for high switching frequency and long life, especially for industrial applications. Multi-flame control in conjunction with flame detector IFW 15/IFW 15 T (see leaflet 6.5).Field of application in accordance with European standards EN 746-2 and EN 676 for intermittent operation. The automatic burner control units are EC type-tested and certified pursuant to the Gas Appliances Directive (90/396/EEC) in conjunction with EN 298. |

|

Flame detector IFW 15

Application

|

|

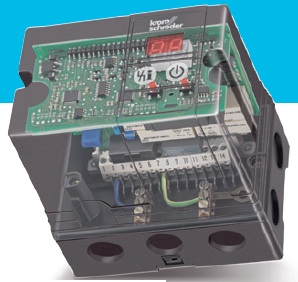

Burner control unit BCU 370

ApplicationIt can be used for directly ignited forced draught burners or forced draught burners ignited with pilot burner. The BCU 370 activates the blower and sets the connected butterfly valve to pre-purging and ignition position. After pre-purge and burner start, the Enable signal is issued to an external controller which positions the butterfly valve in accordance with the output demand. Post-purge occurs after the end of burner operation. The burner control unit BCU 370 monitors the gas and air pressure. An optionally integrated tightness control function checks the valves with an external gas pressure switch. Programmability by means of the optical interface and BCSoft PC software guarantees optimum adaptation to the relevant application. Adjustable start-up attempts and automatic restart which can be activated ensure the high availability of the burner equipment. The quick-start option allows standard-compliant start-up of the forced draught burner without pre-purge after normal shutdown. This avoids unnecessary admission of air into the combustion chamber. The heat output is available as quickly as possible after a temperature demand. The program status, the unit parameters and the level of the flame signal can be read directly from the unit. An integrated Manual mode allows manual start of the burner and setting of the butterfly valve position independently of the central control system. The BCSoft operator-control and setting software provides a powerful tool for start-up and servicing. To reduce the installation and wiring costs Kromschroder offers an optional Profibus-DP interface to transfer the activation signals and feedbacks. The BCU 370 burner control unit controls, ignites and monitors industrial forced draught burners of unlimited capacity in intermittent or continuous operation. |

|

Flame detectors PFF

ApplicationProduct line 700 process firing system controls and monitors burners in industrial furnaces and firing systems, e.g. in the iron and steel, glass and ceramics, plastics, and chemical industries. |

|

Automatic burner control units PFUFor controlling, igniting and monitoring impulse-controlled, modulating or step-by-step controlled gas burners, for continuous operation with ionisation control, for intermittent operation with UV control (with UV sensors of type UVS) or as a variant for continuous operation with UV control (with UV sensor UVD 1). Display of the program status, device parameters and flame signal. Diagnosis and adjustment of device parameters via optical interface, with manual mode and air valve control. |

|

Protective system control FCU 500 |

|

Burner control units BCU 400 |

|

Impulse system MPT 700 |

|

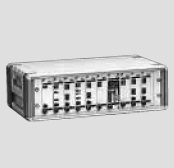

Module subrack BGT SM-8U/1/1 for MPT 700 and PFU 760, PFU 780module subrack, printed-circuit board with rear terminal strip, function-tested, standard documentation, guide rails, without partial front plates, screw terminals at the rear, singlezone operation for MPT 700 operating modes 1-4, two-zone operation for MPT 700 operating modes 1-4, but max. 4 burners per zone. Slot 1 for MPT 700, slots 2 – 9 for PFU 760 or PFU 780, slot 10 for PFP 700 |